The Process of Making blackboard chalk

1) Quarrying the Limestone

After a sufficient reserve of raw limestone has been found, the land that covers the limestone is removed with bulldozers and scrapers. If the chalk is close to the surface, an open shelf quarry method can be used. However chances are that it's deeper in the ground, usually an open pit quarry method is used instead. How this works is holes are drilled into the rock, explosives are placed inside, and the rock is blown apart. (Unknown,2014)

After a sufficient reserve of raw limestone has been found, the land that covers the limestone is removed with bulldozers and scrapers. If the chalk is close to the surface, an open shelf quarry method can be used. However chances are that it's deeper in the ground, usually an open pit quarry method is used instead. How this works is holes are drilled into the rock, explosives are placed inside, and the rock is blown apart. (Unknown,2014)

2) Pulverizing the chalk

Once large chunks of limestone have been quarried, they need to be transported to crushing machines where they are pulverized. The first step is primary crushing. Various crushers exist, but the idea is the same: compress the stone with jaws or a cone, or shatter it through impact. Secondary crushing is done with smaller crushers that work at higher speeds, producing pebbles which are then ground and pulverized. (Unknown,2014)

Once large chunks of limestone have been quarried, they need to be transported to crushing machines where they are pulverized. The first step is primary crushing. Various crushers exist, but the idea is the same: compress the stone with jaws or a cone, or shatter it through impact. Secondary crushing is done with smaller crushers that work at higher speeds, producing pebbles which are then ground and pulverized. (Unknown,2014)

|

3) Grinding, sifting, extruding, and curing chalk The next phase, wet grinding, washes away impurities. This part is necessary to make the limestone suitable for writing purposes. Wet grinding is carried out in ball mills—rotating steel drums with steel balls inside that pulverize the chalk in to fine powder. (Unknown,2014) |

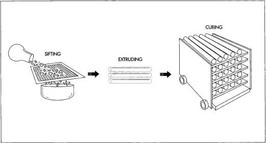

4) Sifting, extruding, and curing chalk

After grinding, the chalk particles are sifted over vibrating filters to separate the finer particles. The particles are then mixed with water, pushed through a well cut out hole, and cut to the proper length. Finally, the chalk is cured in an oven for four days. (Unknown,2014)

After grinding, the chalk particles are sifted over vibrating filters to separate the finer particles. The particles are then mixed with water, pushed through a well cut out hole, and cut to the proper length. Finally, the chalk is cured in an oven for four days. (Unknown,2014)

|

5) Making the chalk (white and coloured)

To make white classroom chalk, the manufacturer adds water to form a thick slurry to the consistency of clay. The slurry is then placed into and pushed out of a hole, in to long thin pieces. Cut into lengths of approximately 62 centimetres, the sticks are placed on a sheet that contains places for five sticks. The sheet is then placed in an oven, where the chalk cures for four days at 85 degrees Celsius. After it has cured, the sticks are cut down to 8 centimetres in lengths. To make coloured classroom chalk, 7 pigments (dry, natural, coloured materials) are mixed in with the chalk mixture while both are dry. This procedure is not unlike sifting flour and baking powder together. Finally water is then added to the mixture and is then baked in the same manner as white classroom chalk. (Unknown,2014) |

6) Packaging and distributing the finished chalk

Placed in small boxes, the completed chalk sticks are stacked in large boxes to be shipped to office supply or art stores. They are usually sold for use at schools, or any place for anyone that uses chalk regardless. (Unknown,2014)

Placed in small boxes, the completed chalk sticks are stacked in large boxes to be shipped to office supply or art stores. They are usually sold for use at schools, or any place for anyone that uses chalk regardless. (Unknown,2014)